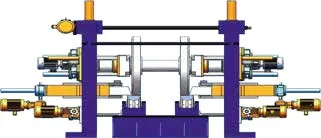

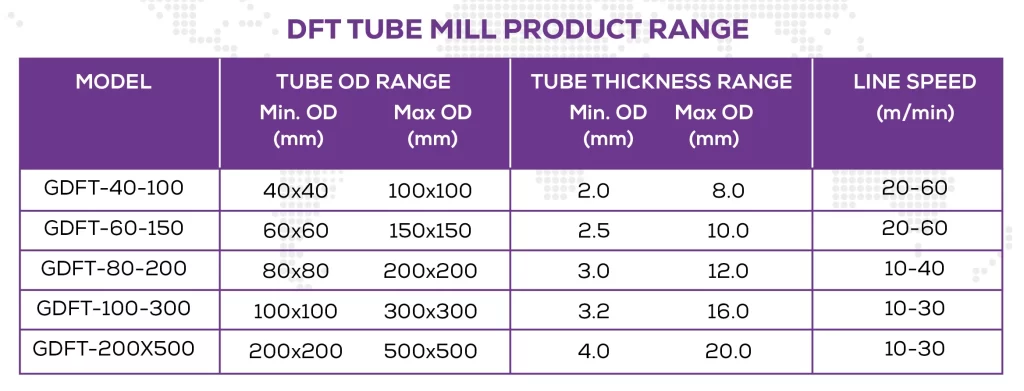

Gallium DFT Tube Mill

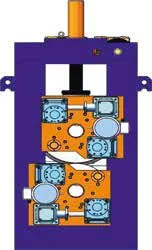

Gallium offers high technology tube mill for section tubes to reduce cost of tooling as well as reduce roll change time. Direct Forming Technology is an advanced manufacturing system designed by Gallium to manufacture wide range of section tubes without roll change. One set of rolls cover complete range of sizes. Any size can be set in 20 minutes with the help of Servo motors & planetary gearboxes. DFT machines represent a crucial asset in modern manufacturing environments, where adaptability, precision, and efficiency are paramount for staying competitive in fast-paced markets.

Key Functions

Direct Shaping: DFT Mill forms square & rectangular sizes directly from flat steel coils without the need for intermediate round tube shaping. This direct forming reduces steps in the manufacturing process.

Reduced Material: Traditional tube mills when reshaping round tubes into squares or rectangles, corner thickening leading more strip width. DFT optimizes material usage by forming the final shape directly.

Production Efficiency: There is no roll change and any size can be set within 20 minutes. After the first production of the roll adjustment, the data such as the servo position of each unit used in this pipe can be stored into the formula and can be custom named. In this way the Mill availability is much higher than conventional mill so production efficiency.

Versatility in Section Sizes: The technology is highly flexible and allows manufacturers to produce tubes of varying section sizes by simply adjusting the rolls. Any section size standard/non-standard can be made immediately without wait for tooling to be manufactured as in conventional Mill. Inventory.

Benefits of using DFT Tube Mills

- Variety of Sizes: Variety of sizes can be made with same tooling.

- No Inventory: Inventory is not required as any size can be made as & when required

- Cost Savings: No Tool cost & No Inventory cost.

- In time delivery: In time delivery is a big advantage for sales person to get order.

- Productivity: Mill availability is much higher in comparison of conventional Mill which increases productivity.