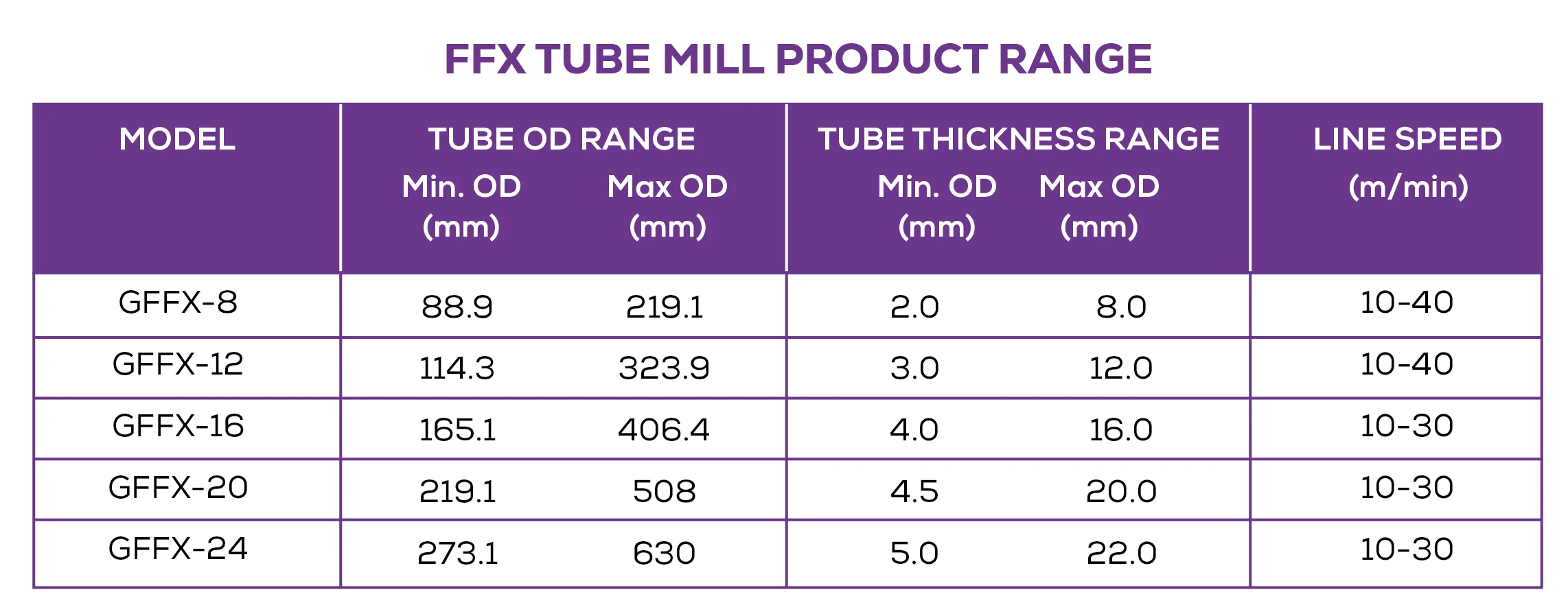

Products > FFX Tube Mill

Gallium FFX Tube Mill

Gallium offers high technology tube mill with common rolls in forming section to reduce cost of tooling as well as reduce roll change time. Forming Flexible Machine is an advanced manufacturing system designed by Gallium to provide versatility

and adaptability in material shaping and forming processes. These machines are engineered to accommodate a wide range of product designs, materials, and production volumes, making them an ideal solution for industries that require high customization and rapid reconfiguration. Forming flexible machines represent a crucial asset in modern manufacturing environments, where adaptability, precision, and efficiency are paramount for staying competitive in fast-paced markets.

Features

- Adaptability: Can be reconfigured for different materials, shapes, and sizes, allowing for quick changes in production processes.

- Automation: Often incorporates advanced control systems and robotics, reducing manual labour and enhancing precision.

- Efficiency and Reduced Lead Time: By minimizing machine changeover times, optimizing material usage, and improving cycle times, these machines contribute to greater overall manufacturing efficiency. Their ability to rapidly switch between different sizes also supports just-in-time production, helping companies respond quickly to market demands

- Customization and Low-Volume Production: Ideal for industries such as aerospace, automotive, and consumer electronics, where custom parts and short production runs are common. The ability to quickly modify tooling and settings allows manufacturers to produce high quality, low-volume, and highly specialized components without significant downtime or retooling costs.

- Advanced Control Systems: Equipped with sophisticated programmable logic controllers (PLCs), Human-Machine Interfaces (HMIs), and real-time monitoring systems, FFX systems offer high precision and consistent quality control across diverse production batches. These machines are often integrated with CNC (Computer Numerical Control) or robotic automation to further enhance operational flexibility and reduce human intervention.